Rubber Diaphragms

High-Quality Rubber Diaphragms for Every Application

We offer a wide range of rubber diaphragms designed for various applications, including flat, molded, fabric-reinforced, and specialized types to meet diverse performance needs.

Diaphragm sizes from 1/4” to 55” diameter

Withstand extreme temperatures

Withstand High Pressure

What Are Rubber Diaphragms?

A rubber diaphragm is a flexible sealing component designed to separate spaces, control pressure, or allow the movement of fluids and gases. Made from high-quality rubber compounds, these diaphragms are essential for applications where a reliable seal and flexibility are required under pressure.Rubber diaphragms are used in a wide variety of industries, including:

Automotive Industry

Used in fuel regulators, valve seals, and pressure systems.

Wind Energy

Instrumentation

Employed in pressure sensors, flow meters, and transducers.

Industrial Equipment

Used in control systems, air compressors, and hydraulic equipment.

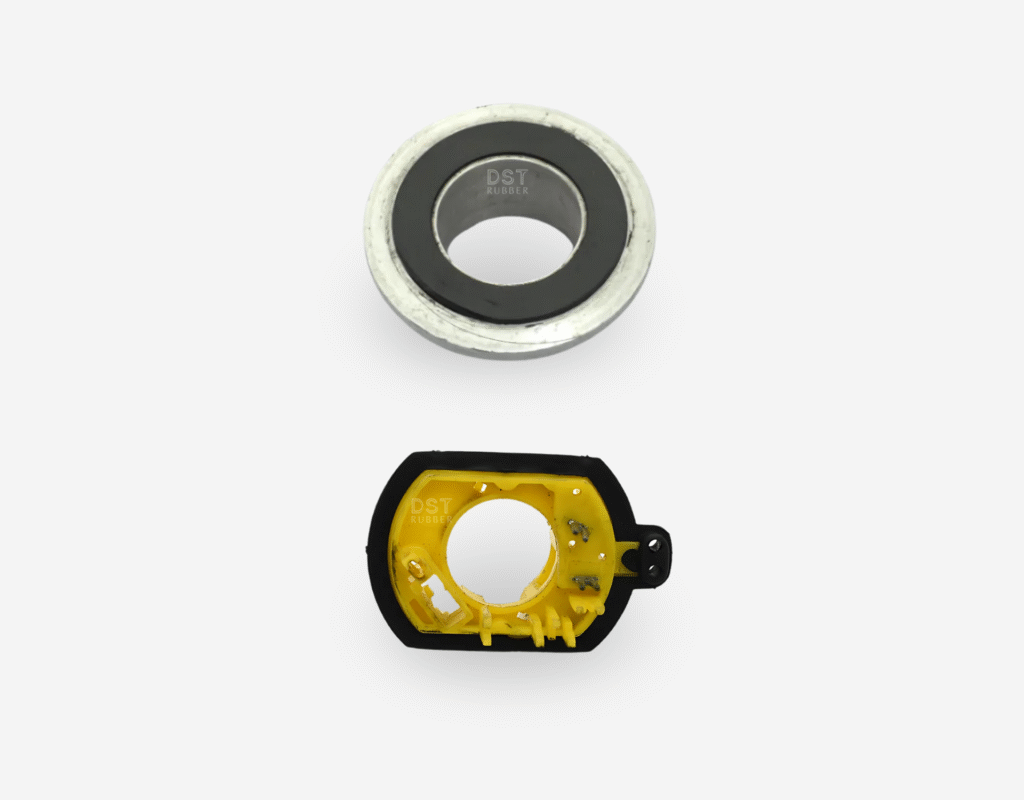

Our Products

Rubber diaphragms are used in a wide variety of industries, including:

Fuel Resistive Diaphragms

Fabric-reinforced diaphragms for LPG/CNG applications, highly sensitive to pressure variations and resistant to high temperatures.

Air Brake Chamber Diaphragms

Essential for truck and bus air brake systems, ensuring optimal braking efficiency and performance.

Pump Diaphragm

Used for transferring fluids in various industries, including agriculture, water treatment, and chemical processing.

Flow Control Diaphragm

Regulate fluid flow in valves, providing on-off and throttle valve functions for precise control.

Windmill Diaphragm

Flexible, weather-resistant diaphragms used to regulate airflow and pressure in windmill systems.

Instrumentation Diaphragm

Precise fluid delivery diaphragms for dosing pumps, ensuring accuracy and reliability in various industries.

Types of Rubber Diaphragms

We offer a wide range of rubber diaphragms designed for various applications, including flat, molded, fabric-reinforced, and specialized types to meet diverse performance needs.

Flat Diaphragms

Simple, flat, and unshaped membranes. Used in low-pressure applications where no pre-formed shape is needed. Commonly employed in basic sealing or low-stress environments.

Flat Molded Diaphragms

Pre-formed to fit specific shapes or profiles. Ideal for applications requiring high precision or complex geometries. Used in pumps, valves, and custom mechanical systems.

Fabric-Reinforced Diaphragms

Embedded with fabric (e.g., nylon, polyester, or aramid) for added tensile strength. Designed to handle high-pressure and high-cycle applications. Common in industrial systems like actuators and compressors.

Rolling Diaphragms

Designed to roll within a housing during motion, minimizing stress and wear. Used in pneumatic and hydraulic cylinders, actuators, and pressure regulators. Offers a longer service life compared to traditional designs.

Perforated Diaphragms

Feature openings or holes for fluid or gas flow while maintaining separation between two chambers. Often used in filtration or flow control applications.

Convoluted Diaphragms

Incorporate flexible ridges or folds (convolutions) to allow for greater movement without overstretching. Suitable for dynamic applications requiring large deflection or displacement.

Dual-Layer or Composite Diaphragms

Made with multiple layers of different materials (e.g., rubber combined with metal or fabric backing). Provide enhanced durability and specific performance traits, such as chemical resistance or rigidity.

Sealing Diaphragms

Thin membranes specifically designed for sealing purposes, preventing fluid or gas leakage. Common in applications such as check valves, pumps, and fluid control systems.

Why Choose DST Rubber Diaphragms?

High-Pressure Resistance

Our diaphragms are engineered to withstand extreme pressure conditions, ensuring longevity and reliability.

Custom Designs

We offer customized diaphragms tailored to specific requirements, including different materials, sizes, and designs.

Precision Manufacturing

Global Standards

Our diaphragms comply with international certifications like FDA, REACH, and RoHS, making them suitable for a variety of industries worldwide.

Features of Our Rubber Diaphragms

High Flexibility and Strength

Ideal for applications requiring constant movement and stress.

Chemical Resistance

Designed to withstand exposure to harsh chemicals, oils, and gases.

Durability

Built for long-lasting performance under both static and dynamic conditions.

Pressure Sensitivity

Sensitive to changes in pressure, ensuring precise performance in pressure-regulating applications.

Custom Rubber Diaphragms for Your Needs

Get in touch today to discuss custom rubber diaphragms tailored to your precise needs!

Industries We Serve

Automotive

Instrumentation and Sensors

Industrial and OEM Applications

Renewable Energy (Windmills)

Hydraulic and Pneumatic Systems

Why DST Rubber?

35+ Years of Expertise

We bring decades of experience in designing and manufacturing custom rubber components.

Precision Engineering

Each diaphragm is crafted with the highest level of attention to detail.

Superior Materials

We use only the finest rubber compounds to ensure durability and performance.

Global Reach

Serving industries in India, the USA, and Germany with high-quality products and on-time delivery.

FAQ

Fabric reinforcement enhances the strength, flexibility, and durability of rubber diaphragms, allowing them to withstand higher pressures and repeated flexing without tearing or deforming. It also improves chemical and temperature resistance, making the diaphragm suitable for demanding applications in pumps, valves, and actuators.

These diaphragms are typically made from high-performance elastomers like Nitrile (NBR), EPDM, Silicone, Fluorocarbon (FKM/Viton®), and Neoprene, combined with reinforcement fabrics such as Nylon, Polyester, Aramid (Kevlar®), or Cotton. The choice of materials depends on factors like temperature resistance, chemical compatibility, and mechanical strength.

Fabric reinforced rubber diaphragms offer several benefits, including:

- Enhanced durability due to fabric reinforcement

- High flexibility while maintaining structural integrity

- Excellent chemical and temperature resistance based on material selection

- Leak-proof and maintenance-free performance in demanding applications

- Cost-effective solution compared to mechanical seals

Selecting the right diaphragm depends on several factors:

- Operating pressure and temperature range

- Compatibility with fluids or gases

- Mechanical stress and expected lifespan

- Industry standards and certifications (e.g., FDA compliance for food-grade applications)

Consulting with a manufacturer can help determine the best material and design for your specific needs.

The lifespan of a diaphragm depends on factors such as material selection, operating conditions, and frequency of use. In ideal conditions, fabric reinforced rubber diaphragms can last several years. However, exposure to extreme temperatures, harsh chemicals, or excessive mechanical stress can shorten their lifespan. Regular inspections and proper material selection can help maximize durability.

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.